NPF Nuova Presso Fondal purchased Daikin air-cooled chillers in 2020. The units are used for cooling and maintaining the temperature of mould cooling water in aluminium die-casting activities.

Challenge: Critical to the die-casting process, NPF’s chillers guarantee the correct temperature of the process water at all times.

Solution: NPF covered the chillers with a maintenance and remote monitoring contract, which includes Daikin on Site connections, to supervise the operation of the units and to ensure fast service interventions.

Highlight: Refrigeration leakage was detected in one chiller and refilled within 4 days without affecting NPF’s normal business activities.

About the Customer

NPF Nuova Presso Fondal SpA, founded in 1947, is a leading company in aluminium die-casting for various types of items, lighting, electric motors, household appliances and so on.

NPF’s manufacturing site in Bosisio Parini (Lecco, Italy) has a 36,000 m² manufacturing area, including a 10,000 m² covered area and a 4,000 m² warehouse.

Since 2020, NPF has been using 3 Daikin chillers for manufacturing activities and cooling purposes.

Let’s hear from our customer NPF

“In industrial aluminium die-casting processes, it’s critical to guarantee the correct temperature of the process water at all times. We turned to a reliable HVAC-R partner with remote monitoring and maintenance services to help us detect and resolve any issues timely,” said Alessandro Giambrone, Maintenance Manager at NPF Nuova Presso Fondal SpA. “We placed trust in Daikin’s 100-year experience and reputation for innovative cooling innovations. During the first 3 years of operation, Daikin’s smart leak detection features and automatic alerts have made all the difference to prevent any operational downtimes at our factory.”

Products installed

- 2 Daikin chillers with 300 kW cooling capacity, model EWAD300TZ

- 1 Daikin chiller with 770 kW cooling capacity, model EWAD300TZ

- 1 dry-cooler provided by a third party

The 3 Daikin chillers cool a 5,000-litre water storage tank, which consequently feeds 2 different circuits in the foundry.

- 1st circuit represents the cooling of the hydraulic and hybrid presses equipped with plate exchangers installed on board the presses, creating a closed circuit.

- 2nd circuit represents the cooling of the moulds, which by means of 2 large plate exchangers installed in the technological plant room, cools a second accumulation of approximately 10,000 litres in open circuit.

The dry-cooler is used in the winter period by exploiting the ambient temperature up to a maximum of 20°C in combination with chiller 3, which brings the temperature back to the operating value in the foundry between 17°C and 18°C when needed.

Each component of the cooling plant is managed and supervised by a Programmable Logic Controller (PLC) and a control panel, remotely controlled as required by Industry 4.0.

Benefits

NPF’s Remote Monitoring and Maintenance service contract with Daikin:

- Units are maintained properly and monitored remotely and reliably by Daikin on Site

- Service technicians automatically receive alerts specifying the type of alarm and any predictions

- Goals: To allow service technicians to equip themselves with the right tools before going on site and intervene in a timely manner.

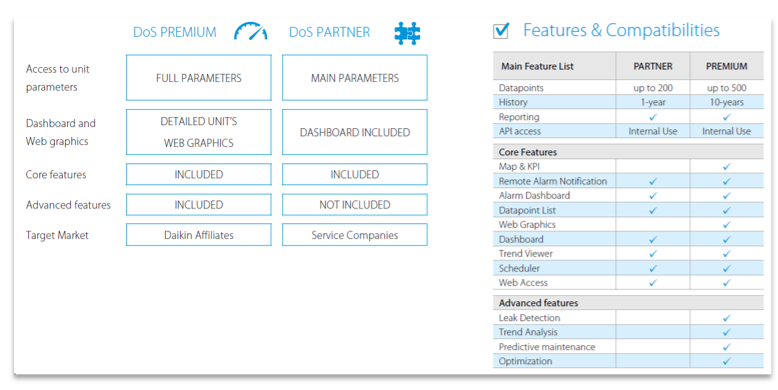

Daikin on Site Premium package includes:

- Advanced features such as leak detection, trend analysis, predictive maintenance and optimisation

- Goals: To detect and resolve issues timely and avoid downtime for production.

Proof point

After receiving an alarm on the Daikin on Site screen, Daikin engineers immediately checked with an Authorised Service Center to define the root cause of the refrigerant leakage, troubleshooted the problem and refilled the refrigerant within 4 days on the EWAD770TZ chiller. Operational downtime was prevented!

The results

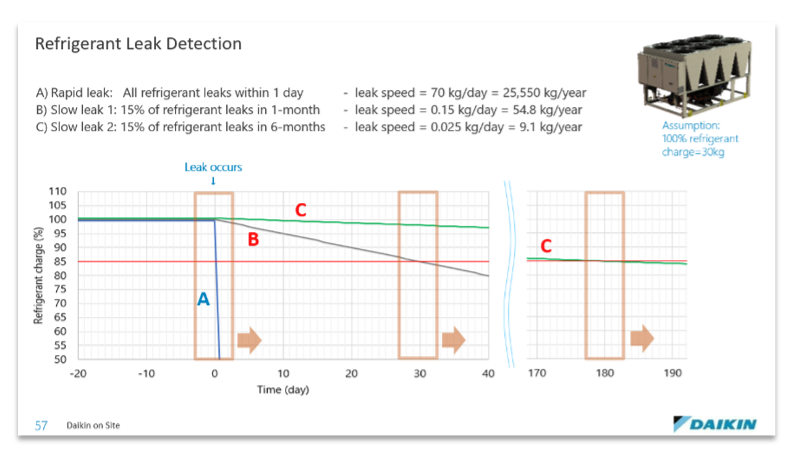

The leak resulted in a loss of 15 kg of refrigerant on a total of 104 kg refrigerant in the unit. This meant only 14% of the total unit refrigerant was lost.

Without the leak detection feature, it would have taken months to detect this leak, at a much bigger cost, for the environment and also economically for replacing the refrigerant.

Advantages for customers with Daikin on Site

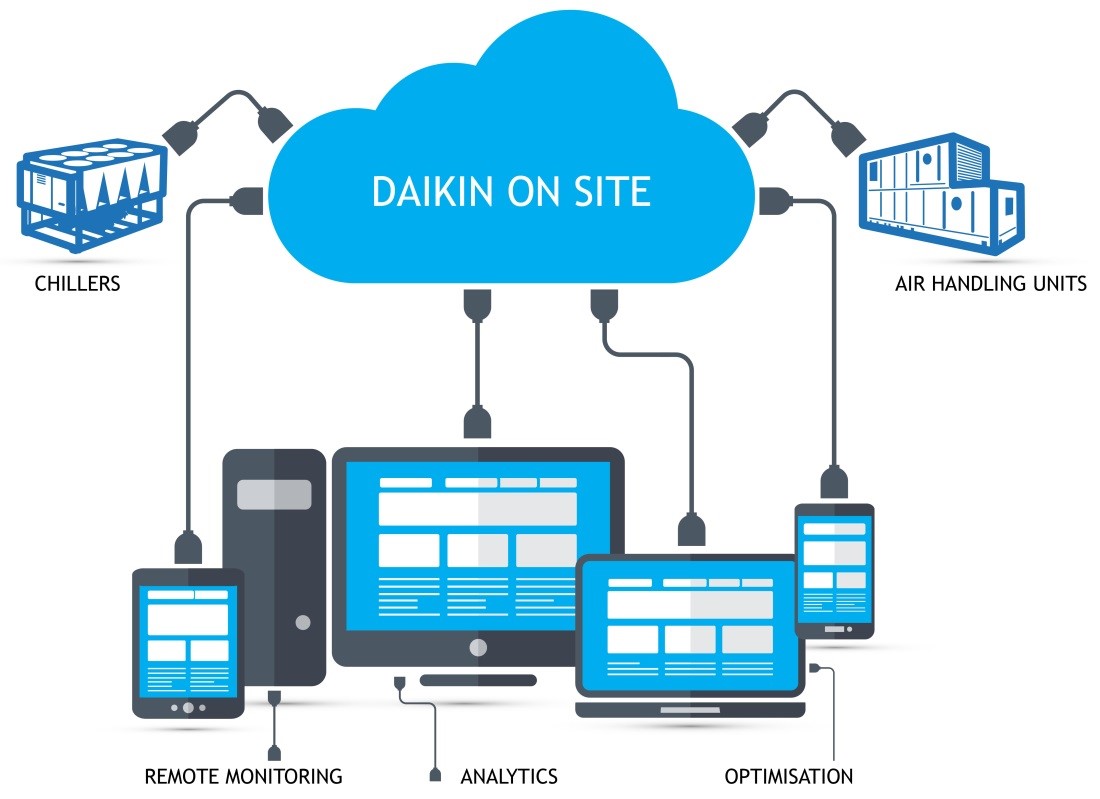

Cloud-based remote monitoring and control tool that assists and informs customers about their chiller plants and air handling units.

- Provide real-time data access and storage

- Support from Daikin experts

- Identify cost-saving opportunities

- Increase the lifetime of the unit

- Reduce the risk of unexpected issues

How the Leak Detection feature works

The algorithm takes data into account that are related to the last 4 months of the unit’s operation. When a refrigerant leak is detected, Daikin on Site promptly notifies the pre-specified end-user, installer and service engineer by the following means:

- Alarm display on the Daikin on Site screen

- Sending mail to a previously registered mail address

- Completing the above notification within one minute of detecting the leak

- Option to cancel the alarm if it is judged to be a false alarm.

What’s next?

The refrigerant leak detection algorithm is constantly being improved by Daikin experts with increased accuracy and deployment in more units. The logic is available for EWAD-TZD, EWAT-B-C chillers and will be implemented in new Daikin chillers.

.png)